And the working area of the die is 200 X 150 mm. It describes the various components of a cold-heading machine and the.

How It Works Cold Forming Makes Fasteners And A Lot More Today S Machining World

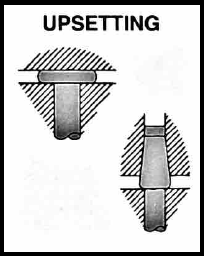

Heading Basics Introduction to Cold Heading Cold heading is a cold forming process that essentially involves applying force with a punch to the end of a metal blank contained in a die.

. 1-18 Jern Yao Model 36B4S 4 Die 5 Station. The site of the cold chambers should be decided o nce the sizes are known but as a general rule they should be in the shade of direct sunlight. Bruno Ninaber van Eyben in Manufacturing and Design 2014.

24 Die Set Structure The die set designed as per design data 5. Introduction to Cold Heading Cold heading is a cold forming process that essentially involves applying force with a punch to the end of a metal blank contained in a die. Cold Header Tooling Design For over 50 years Sieber Tooling Solutions has designed and engineered high-quality metal forming tools and solutions for use in.

Cold Heading Cold heading or cold forming is the process of manufacturing parts at high speeds by changing the shape of a length of an unheated coiled wire that has been inserted into a die. Hex Punches Six-Lobe Punches Inner-Hexagon Punches etc and other custom-made punches. A general guideline for cold formability is that the metals elongation must be at least 20.

They may be stick built on site as individual members or panelized into pre-assembled systems for walls floors or. High structural integrity Microstructurallyforgings are optimalachieving 100 density in contrast to porosity-prone castings. 18 Carlo Salvi PSV DSSD High Speed Cold Header.

Custom Cold Forming Cold Heading. The force must exceed the metals elastic limit yield strength to cause plastic flow. Steels for cold heading and cold extruding conforming to IS 1984 4.

The top plate is designed as a pillar die set with a rectangular working space. Make one of the forced extrusion type and one of the open type. The following table is some parameter according to material.

Clinch Fetters Knurls Threads. Consult with the forger to determine the net shape capability and. The shank is fixed.

These include headers transfer headers bolt makers nut formers and parts formers. View Properties Table Useful Links. Cold heading design guide Figure 3-24 Minimize diameter ratios.

There may be some confusion in above translation please click the link in picture then you will go to URL about series of punches and watch pictures directly. Make sketches with typical dimensions showing forward extrusion. CFSF products include cold-formed studs joists rafters trusses and miscellaneous bracing and connection components.

The wire is fed automatically into a cold heading machine and a predetermined blank of material is cut-off and automatically placed in line with a cavity called a die. Typical cold formed tolerances are shown on the diagrams. Guide Basic Steps of Cold Forming Cold forming the chosen material into a given part shape is governed by that materials structural properties.

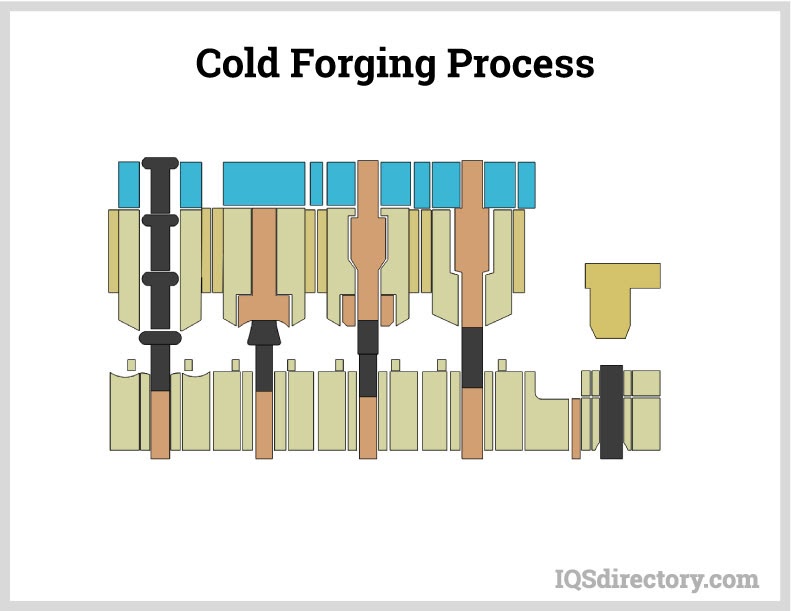

One-dimensional guide rail unfolding mechanism longitude and latitude unfolding mechanism and One-dimensional wheel unfolding mechanism. Cold forged parts are generally produced on multi-station machines called headers or a combination of single-station presses. Cold heading is typically a high-speed process where a blank is progressively moved through a multi-station machine.

This publication is intended as a guide for designers of cold-formed steel framing CFSF systems for buildings. Cold-Formed Steel Framing Design Guide. Material for Cold Forming This a list admittedly incomplete of metals suitable for cold forming and some that are not.

Fastcos cold headed pin production capabilities include heading single die design and multiple die design. Exceed the design-stress calculationsIn additionthe much greater strength-to-weight ratio of forgings facil-itates the design of lighter-weight parts with corre-sponding cost savingsand without sacrificing safety. Avoid undercut diameters in products to be cold forged.

Cold-heading revolves around the concept of altering an initial steel blank through force using a series of tools and dies to change the blank into a finished product. The force must exceed the metals elastic limit yield strength to cause plastic flow. These properties help make up the rules of how to form parts all based on the combination of 3 basic forming methods.

This work develops a process that solves the problem of the formation of cracks inside forged gas fittings in the cold forging process that arises from poor forging process design. 24 mm National 245 FC 5 Die. Tighter tolerances can be held if needed.

MAThread MATpoint Design. Cold Heading Design Guide Manufacturers Factory Suppliers From China If needed welcome to make contact with us by our web page or phone consultation we will be delighted to serve you. Cold Heading Design Guide.

In the cold heading process fracture under tensile stresses can occur although the materials used are ductile. This article discusses various cold heading process parameters such as upset length ratio upset diameter ratio upset strain and process sequence design. When the number of required processes is more than the.

Fastco Industries maintains complete in-house cold forming engineering design and simulation capabilities in support of all of our manufacturing processes. Cold Heading Cold heading or cold forming is the process of manufacturing parts at high speeds by changing the shape of a length of an unheated coiled wire that has been inserted into a die. It may be considered a forging operation without heat.

By arranging the forming of a part in stepsstations using the above basic processes the sequence design is cre-ated. It may be considered a forging operation without heat. Cold heading is typically a high-speed process where a blank is progressively moved through a multi-station machine.

The overall dimension of die set is 315 X 250 mm. Further Fastco completely designs and fabricates its own custom cold heading tooling including multiple upset configurations custom head shapes and substitutions for multi-part assemblies. Ad Engineering Consulting and Part Development Expertise.

Make a sketch with typical dimensions showing backward extrusion. The actual volume of steel remains unchanged but the process maintains or improves its overall tensile strength. Tooling set up were able to put.

Return to Table of Contents array markup 1.

Cold Forging What Is It Benefits Process Hot Vs Cold Types Considerations

What Is Cold Heading Grandeur Fasteners Inc

Cold Forming Overview And Reference Guide The Federal Group Usa

What Is Cold Heading Grandeur Fasteners Inc

Cold Forging What Is It Benefits Process Hot Vs Cold Types Considerations

Cold Forming Overview And Reference Guide The Federal Group Usa

Cold Forming Overview And Reference Guide The Federal Group Usa

Cold Forming Overview And Reference Guide The Federal Group Usa

0 comments

Post a Comment